The photothermal conversion LTHC coating is a solvent based, spin on ink coating. A glass release coating specifically designed for temporary bonding and debonding of WSS wafers.

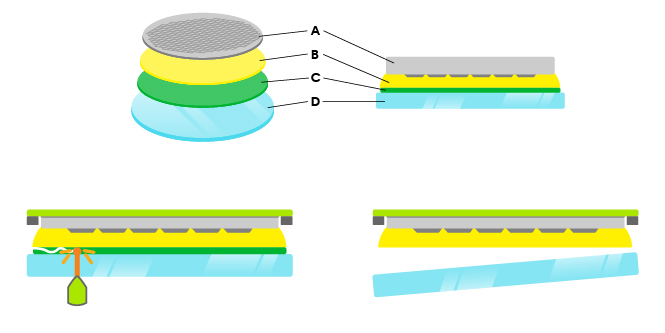

Photothermal conversion during temporary bonding and peeling processes

A. Semiconductor wafer

B. UV curable adhesive LC-3200

C. Thermal Thermal Conversion Coating (LTHC)

D. Glass carrier

The photothermal conversion coating (LTHC) improves the efficiency of semiconductor wafer processing. It forms a coating between the glass carrier and the adhesive, converting light into heat during laser irradiation - which helps reduce the laser intensity required for peeling. This photothermal conversion can also achieve clean adhesive dissociation with minimal force at room temperature, maintaining the integrity of the glass carrier for reuse and recycling.